How a Water pH Sensor Helps Prevent Pipe Corrosion

Pipe corrosion is a major concern in water supply systems, industrial processes, and plumbing networks. Over time, acidic or highly alkaline water can damage pipes, reduce system efficiency, and lead to costly repairs. Monitoring pH levels is therefore critical for maintaining water quality and protecting infrastructure. A water pH sensor provides the precise data needed to prevent corrosion and ensure the longevity of pipes and related equipment.

The Role of pH in Pipe Corrosion

Water with a low pH (acidic) can accelerate the corrosion of metal pipes, causing leaks, structural weakness, and contamination. On the other hand, water with high pH (alkaline) can lead to scale formation, which also impacts system efficiency and can cause localized corrosion beneath deposits.

A water ph sensor allows operators to continuously monitor the acidity and alkalinity of water in real time. By providing accurate measurements, the sensor enables timely adjustments to water chemistry, preventing conditions that lead to corrosion or scaling and maintaining the integrity of piping systems.

How a Water pH Sensor Works

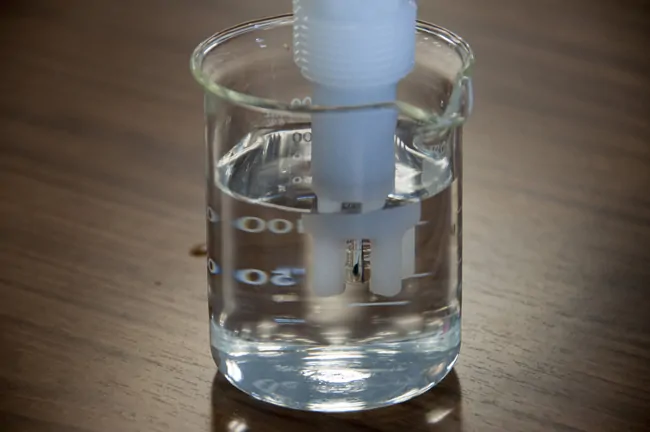

Water pH sensors operate using a measuring electrode that interacts with hydrogen ions in the water and a reference electrode that provides a stable baseline. The resulting voltage difference is converted into a pH value, which is then displayed or transmitted to a monitoring system.

Modern sensors often include temperature compensation, ensuring reliable readings even in water with fluctuating temperatures. Durable electrode materials and protective housings make these sensors suitable for long-term use in pipelines, industrial water systems, and municipal networks.

Applications in Corrosion Prevention

In industrial and municipal water systems, pH sensors are installed at strategic points to continuously track water quality. Real-time monitoring allows operators to detect deviations early and take corrective action, such as adjusting chemical dosing, introducing corrosion inhibitors, or balancing water treatment processes.

In heating and cooling systems, pH monitoring helps prevent damage to boilers, condensers, and heat exchangers caused by acidic or alkaline water. By maintaining optimal pH levels, operators can reduce maintenance costs, extend equipment life, and improve operational efficiency.

Integration With Automated Systems

Water pH sensors can be integrated into automated water treatment and control systems. When the pH falls outside the desired range, the system can automatically adjust chemical dosing or trigger alerts for manual intervention.

This automation ensures consistent protection against corrosion without requiring constant manual monitoring. Continuous logging of pH data also allows for trend analysis, predictive maintenance, and regulatory compliance reporting, further supporting proactive management of water systems.

Factors Affecting Sensor Accuracy

The performance of a water pH sensor depends on proper maintenance, calibration, and environmental conditions. Fouling from minerals, biofilm, or chemical residues can reduce electrode sensitivity. Extreme temperatures, sudden chemical changes, or prolonged exposure to harsh substances may also impact readings.

Regular calibration with standard buffer solutions, cleaning of electrodes, and adherence to manufacturer guidelines help maintain accurate performance. Selecting a sensor compatible with the water chemistry and operational environment ensures reliable measurements over time.

Benefits of Using a Water pH Sensor

Monitoring pH with a sensor provides a proactive approach to preventing pipe corrosion. Accurate readings enable proper chemical dosing, reduce repair costs, and prolong the life of pipes and associated equipment. Continuous monitoring also improves safety, prevents water quality issues, and supports regulatory compliance in industrial and municipal applications.

Conclusion

A water pH sensor is an essential tool for preventing pipe corrosion, ensuring that water chemistry remains within safe limits for metal infrastructure. By providing precise, real-time measurements, these sensors allow operators to detect and correct problematic conditions early. Integrating pH monitoring into automated systems, performing regular maintenance, and following proper calibration practices ensures reliable protection against corrosion, reduces operational costs, and extends the lifespan of piping networks in diverse applications.