Custom Solutions From Agitated Nutsche Filter Dryer Manufacturers

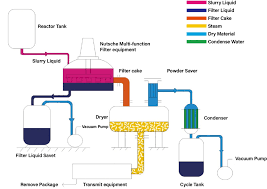

Agitated Nutsche Filter Dryers (ANFDs) have become essential equipment in chemical, pharmaceutical, and fine chemical industries due to their ability to integrate filtration, washing, and drying in a single vessel. While standard models meet many operational requirements, manufacturers increasingly demand custom solutions to address unique process needs, improve efficiency, and ensure product quality. Customization allows businesses to tailor equipment to handle specific materials, batch sizes, and regulatory requirements, ensuring optimized performance in demanding industrial environments.

An Agitated Nutsche Filter Dryer Manufacturer plays a pivotal role in providing these custom solutions. Experienced manufacturers work closely with clients to understand process requirements, material characteristics, and operational constraints. For industrial-grade, customizable options and detailed specifications, you can explore this Agitated Nutsche Filter Dryer Manufacturer, which is recognized for delivering flexible and reliable systems for a wide range of applications.

Understanding the Need for Custom Solutions

While off-the-shelf ANFDs meet general processing needs, many industries require equipment tailored to their specific products or processes. Custom solutions can address unique challenges, such as handling heat-sensitive materials, processing abrasive solids, or achieving precise moisture content in the final product. Additionally, batch sizes, vessel configurations, and filtration media may vary depending on production volumes and chemical characteristics.

Customization ensures that the equipment operates efficiently, reduces downtime, and maintains consistent product quality. It also allows manufacturers to comply with stringent regulatory standards, particularly in pharmaceutical and food processing applications, where contamination control and sanitary design are critical.

Key Customization Options

Agitated Nutsche Filter Dryer manufacturers offer a variety of customization options to meet client-specific requirements:

Vessel Design and Material Selection

Vessel size, geometry, and material composition can be customized based on the nature of the product and production scale. Stainless steel is commonly used due to its corrosion resistance and sanitary properties, but specialized alloys such as Hastelloy, titanium, or duplex stainless steel may be required for aggressive chemicals. Conical or rounded vessel bottoms can improve solids discharge, while customized jacketed designs ensure efficient heat transfer during drying.

Agitator Configuration

The agitator is critical for uniform mixing, preventing cake formation, and ensuring effective drying. Manufacturers can customize agitator type—plough, paddle, or anchor—and blade design to suit product viscosity, particle size, and abrasiveness. Properly designed agitators reduce the risk of mechanical damage to the product and minimize maintenance requirements.

Filtration Media

The choice of filtration media is essential for effective separation of solids and liquids. Customization may include woven stainless steel cloth, synthetic fabrics, or perforated metal plates. Media can be selected based on particle size, chemical compatibility, and desired filtration rate, ensuring efficient operation and consistent product quality.

Heating and Vacuum Systems

Temperature-sensitive products require precise control over drying conditions. Manufacturers can tailor heating jackets, filter plate temperatures, and vacuum levels to optimize drying without compromising product integrity. Advanced designs may incorporate multiple heating zones, steam or thermal oil circulation, and vacuum-assisted drying systems for improved efficiency.

Discharge Mechanisms

Efficient discharge is crucial to prevent product loss and reduce manual handling. Custom ANFDs can include bottom valves, tilting vessels, or mechanical scrapers designed for smooth, complete discharge. These modifications reduce residue, enhance safety, and improve process reliability.

Integration of Automation and Monitoring

Modern custom ANFDs often incorporate advanced automation and monitoring systems. Sensors for temperature, vacuum, and agitation speed provide real-time data, enabling operators to optimize filtration, washing, and drying cycles. Automated controls and process analytics reduce human error, improve reproducibility, and increase overall efficiency. Integration with manufacturing execution systems (MES) allows for predictive maintenance and remote monitoring, further enhancing operational reliability.

Regulatory and Safety Considerations

Custom ANFDs are often designed to meet specific regulatory and safety requirements. Pharmaceutical and food-grade applications require cGMP-compliant surfaces, smooth welds, and CIP-compatible designs to minimize contamination risks. Manufacturers can also provide explosion-proof motors, inert gas purging, and advanced pressure relief systems to ensure safe operation with hazardous or flammable materials.

Benefits of Custom Solutions

Custom-designed Agitated Nutsche Filter Dryers offer multiple advantages:

- Optimized Performance: Tailored equipment ensures consistent filtration, washing, and drying for specific products.

- Reduced Downtime: Properly configured agitators, vessels, and discharge systems reduce maintenance and operational delays.

- Enhanced Product Quality: Customized solutions maintain uniform particle size, moisture content, and chemical integrity.

- Regulatory Compliance: Designs meet industry-specific standards, reducing risk during inspections and audits.

- Operational Safety: Advanced safety features protect operators and reduce exposure to hazardous materials.

Conclusion

Custom solutions from Agitated Nutsche Filter Dryer manufacturers are increasingly important for industries that require precision, efficiency, and compliance. Tailored designs for vessel geometry, agitator type, filtration media, heating, and discharge systems ensure optimal operation and product quality. By incorporating advanced automation, safety features, and regulatory compliance measures, manufacturers can provide ANFDs that meet the specific needs of chemical, pharmaceutical, and fine chemical industries. Investing in a custom-designed ANFD not only improves process efficiency but also enhances safety, reliability, and overall production outcomes.