Maintenance Tips for Industrial Marking Machines

Industrial marking machines are essential tools in modern manufacturing, providing accurate, durable, and efficient product identification. To ensure optimal performance, minimize downtime, and extend machine lifespan, regular maintenance is crucial. Implementing a structured maintenance plan helps manufacturers maintain consistent marking quality, reduce repair costs, and improve overall production efficiency.

Working with a trusted industrial marking machine manufacturer can provide valuable guidance on maintaining your equipment. Experienced manufacturers offer recommendations on cleaning procedures, replacement schedules for consumables, and troubleshooting strategies. Their support ensures that machines operate reliably while preventing common issues that can disrupt production.

Regular Cleaning and Inspection

One of the most important maintenance practices is keeping the machine clean. Dust, debris, and ink residue can accumulate on the machine components, affecting performance and mark quality. For inkjet printers, regularly cleaning nozzles and print heads prevents clogging, while laser marking machines require periodic lens cleaning to maintain precision. Dot peen machines should have the stylus and marking area cleaned to ensure consistent indentation.

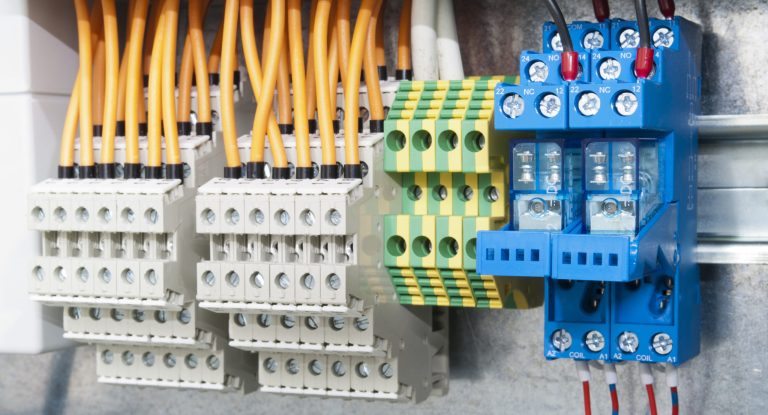

Routine inspections allow operators to identify worn or damaged parts before they lead to machine failure. Checking belts, electrical connections, moving parts, and mechanical components helps detect early signs of wear and enables timely replacements.

Proper Handling of Consumables

Consumables such as ink, ribbons, and laser optics play a critical role in the operation of industrial marking machines. Using high-quality consumables recommended by the manufacturer ensures consistent marking quality and reduces the risk of damage to the machine. For inkjet systems, storing ink properly and replacing it before expiration prevents clogging and poor print quality. Thermal transfer ribbons should be handled carefully to avoid contamination or tearing, which can impact label clarity.

Calibration and Alignment

Maintaining accurate calibration and alignment is vital for producing consistent markings. Machines should be calibrated regularly according to manufacturer specifications. Misalignment can result in off-center or incomplete marks, compromising traceability and product quality. Automated calibration features in modern machines simplify this process, but periodic manual checks are recommended to verify precision.

Lubrication and Mechanical Maintenance

Machines with moving mechanical parts, such as dot peen or rotary marking systems, require regular lubrication to reduce friction and wear. Proper lubrication enhances smooth operation and prolongs the lifespan of critical components. Always use manufacturer-approved lubricants and follow recommended schedules. Additionally, checking fasteners, belts, and guides ensures that mechanical systems remain stable and function efficiently.

Software Updates and System Checks

Many industrial marking machines rely on software for programming and operation. Keeping software and firmware up to date ensures compatibility, improves performance, and addresses known issues. Regular system checks help identify software errors, incorrect settings, or communication problems with automated production lines. Proper software maintenance reduces downtime and ensures that machines operate reliably.

Operator Training and Best Practices

Well-trained operators are essential for maintaining industrial marking machines. Training should cover proper handling, routine maintenance tasks, troubleshooting, and safety protocols. Operators who understand the machine’s functions and limitations can identify potential issues early and perform basic maintenance correctly. Encouraging adherence to best practices enhances machine longevity and minimizes the risk of operational errors.

Scheduled Preventive Maintenance

Preventive maintenance involves conducting routine checks and servicing at scheduled intervals, rather than waiting for a breakdown. Following the manufacturer’s maintenance schedule ensures that all critical components are inspected, cleaned, or replaced as needed. Preventive maintenance reduces unexpected downtime, improves production efficiency, and extends the overall lifespan of the machine.

Conclusion

Regular maintenance is essential for keeping industrial marking machines operating efficiently and producing high-quality marks. By following best practices such as cleaning, calibration, lubrication, software updates, and operator training, manufacturers can minimize downtime, reduce repair costs, and maintain consistent product quality. Partnering with a reliable industrial marking machine manufacturer provides expert guidance, recommended maintenance schedules, and ongoing support to ensure machines perform optimally. Implementing a proactive maintenance plan is a strategic approach that enhances productivity, safeguards equipment investment, and supports long-term success in manufacturing operations.