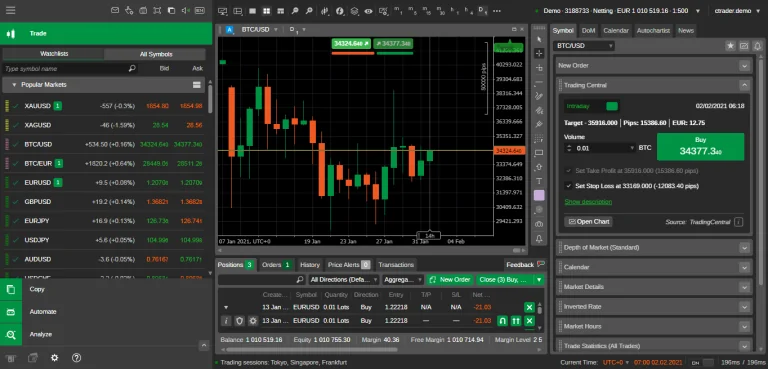

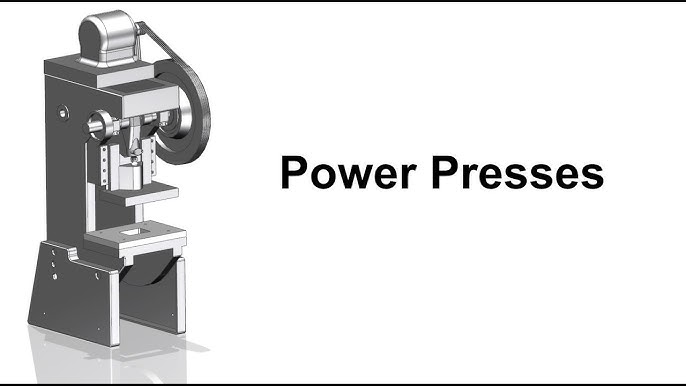

Power Press Manufacturers and Industrial Compliance Standards

Power press machines are vital in manufacturing industries, performing operations such as punching, bending, forming, and cutting metal sheets. With high operational forces and repetitive cycles, these machines require precise engineering, quality construction, and adherence to safety regulations. Compliance with industrial standards ensures that presses operate safely, efficiently, and reliably while meeting regulatory requirements. Power press manufacturers play a crucial role in designing and producing machines that align with these standards.

A reliable Power Press Manufacturer ensures that each machine meets national and international compliance requirements. This includes following safety regulations, quality certifications, and operational standards to reduce the risk of workplace accidents and machine failures. By integrating compliance into the design, manufacturing, and testing processes, manufacturers provide clients with reliable, safe, and high-performance presses suitable for diverse industrial applications.

Importance of Compliance Standards

Industrial compliance standards are essential for several reasons. First, they protect operators from potential hazards by enforcing safety features such as guards, interlocks, emergency stops, and two-hand control systems. Second, compliance guarantees machine quality and reliability, preventing unexpected downtime or damage to components. Third, adherence to recognized standards allows manufacturers to operate globally, as international clients require evidence of safety and performance compliance. Without strict compliance, presses may pose serious risks to operators and production quality.

Key Compliance Standards for Power Presses

Several key standards guide power press manufacturers in ensuring compliance. These standards cover design, materials, safety, and performance requirements.

ISO Standards

The International Organization for Standardization (ISO) provides a framework for quality management and operational efficiency. ISO 9001 certification ensures that manufacturers have consistent processes, proper documentation, and continuous improvement practices. ISO standards also provide guidance for environmental management, ensuring that production processes are sustainable and safe.

CE Marking and European Safety Directives

In European markets, CE marking is mandatory for power press machines. This certification verifies compliance with directives related to machinery safety, including operator protection, electrical safety, noise control, and vibration levels. Manufacturers producing CE-certified presses demonstrate that their machines meet strict safety regulations and are suitable for use in international industrial environments.

Material and Structural Compliance

Material selection and structural design are critical for compliance. High-strength steel, cast iron, and alloys are used for frames, rams, and flywheels to withstand repeated operational forces. Compliance standards dictate tolerances, alignment criteria, and fatigue resistance to ensure longevity and consistent performance. A well-constructed press reduces the likelihood of component failure, protecting both operators and production processes.

Safety Device Standards

Safety devices must adhere to compliance standards that govern emergency stops, light curtains, interlocks, two-hand controls, and guards. Power press manufacturers integrate these systems during design and production to prevent accidental access to moving parts. Properly designed safety devices reduce workplace accidents and ensure adherence to occupational health and safety regulations.

Testing and Performance Verification

Compliance also requires rigorous testing of power presses before delivery. Manufacturers perform load testing, alignment verification, stroke accuracy checks, and safety feature inspections. Hydraulic and mechanical presses are evaluated at maximum rated tonnage to ensure they operate safely under full load. Testing ensures that each machine meets its specifications and maintains compliance throughout its service life.

Benefits of Compliance for Manufacturers and Clients

Adherence to compliance standards benefits both manufacturers and clients. For manufacturers, it demonstrates professionalism, improves brand reputation, and enables access to global markets. For clients, it ensures operational safety, consistent performance, and reduced risk of downtime. Compliance also supports long-term cost savings by minimizing accidents, component failures, and maintenance issues.

Continuous Improvement and Regulatory Updates

Industrial standards and safety regulations are continuously evolving. Leading power press manufacturers invest in research and development, monitoring regulatory changes and updating their machines accordingly. Continuous improvement practices, combined with periodic testing and staff training, ensure that presses remain compliant and capable of meeting modern industrial requirements.

Conclusion

Compliance with industrial standards is a cornerstone of power press manufacturing. By adhering to ISO certifications, CE marking requirements, material and structural standards, and rigorous safety protocols, manufacturers ensure that every press machine is safe, durable, and efficient. A reputable Power Press Manufacturer integrates compliance into all aspects of design, production, and testing, providing machines that meet the demands of modern industries while safeguarding operators and maintaining performance reliability. Industrial compliance not only protects personnel but also enhances productivity and operational longevity, making it a critical factor in the success of any manufacturing operation.