Inventory and Supply Chain Optimization Software

Inventory and Supply Chain Optimization Software

In today’s fast-paced business environment, the need for efficient inventory and supply chain management has never been more critical. As businesses strive to meet growing customer demands, control costs, and optimize operations, inventory and supply chain optimization software has become an essential tool in streamlining processes, reducing inefficiencies, and driving growth.

This article explores how inventory and supply chain optimization software can help businesses enhance their operations, improve decision-making, and optimize their entire supply chain, from procurement to delivery.

What Is Inventory and Supply Chain Optimization Software?

Inventory and supply chain optimization software refers to tools and systems designed to help businesses manage and streamline their supply chain processes, from procurement and warehousing to distribution and delivery. These solutions integrate inventory management, demand forecasting, supplier management, and transportation logistics to ensure products are delivered to the right place, at the right time, and at the lowest possible cost.

The software aims to optimize each stage of the supply chain by improving visibility, increasing efficiency, reducing waste, and minimizing stockouts or overstocking.

Key Features of Inventory and Supply Chain Optimization Software

To optimize the entire supply chain, businesses need a comprehensive solution that integrates various aspects of inventory management and logistics. Below are some of the key features that businesses should look for in inventory and supply chain optimization software:

1. Real-Time Inventory Tracking

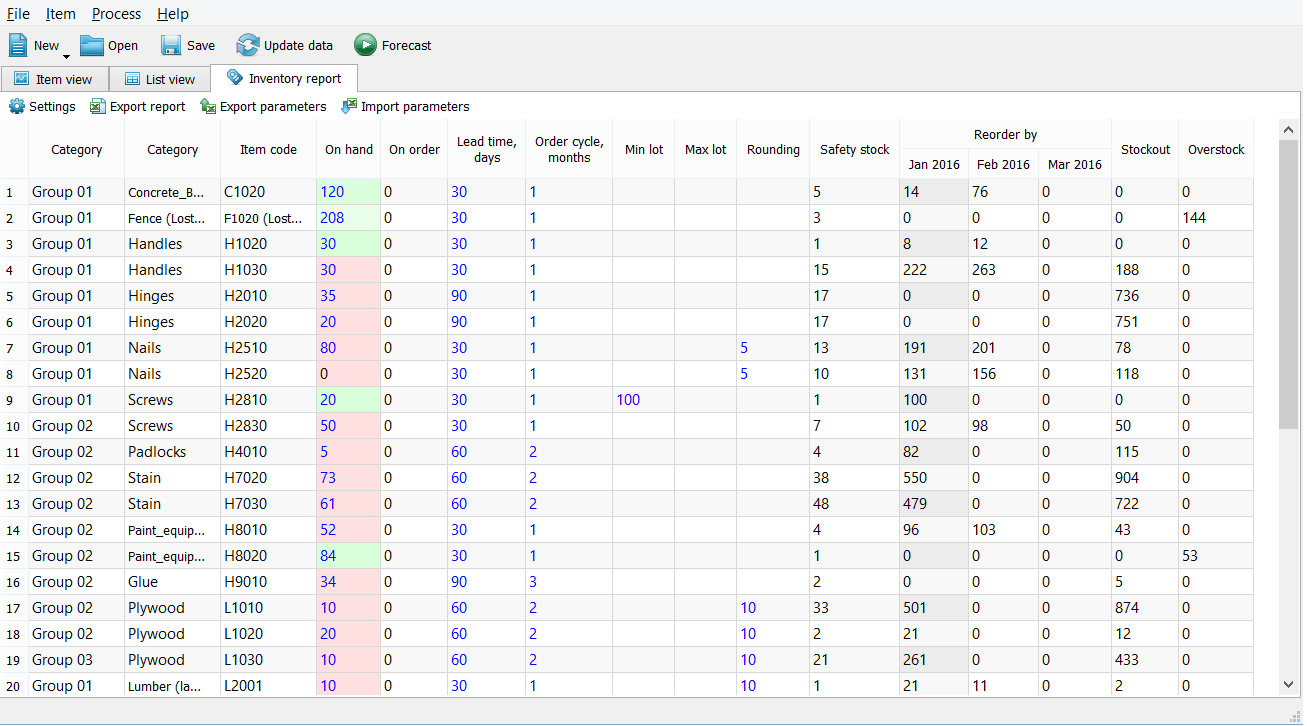

Real-time inventory tracking allows businesses to monitor stock levels across various locations and warehouses. It provides up-to-date visibility into inventory, ensuring that businesses can make informed decisions about stock replenishment, transfers, and order fulfillment. Real-time tracking helps reduce the risk of stockouts and overstocking, optimizing inventory levels across the entire supply chain.

2. Demand Forecasting and Planning

Effective demand forecasting is crucial for supply chain optimization. Inventory and supply chain optimization software typically includes demand forecasting tools that use historical data, market trends, and other relevant factors to predict future demand. This helps businesses plan inventory levels more accurately, ensuring they have the right products available at the right time without overstocking.

3. Automated Replenishment

Automated replenishment functionality allows the software to automatically reorder products when stock levels fall below predefined thresholds. By integrating inventory data with suppliers, businesses can ensure that stock is replenished in a timely manner, reducing lead times and minimizing stockouts. This automation helps maintain optimal inventory levels without manual intervention.

4. Supplier and Vendor Management

Managing relationships with suppliers and vendors is crucial to an efficient supply chain. Optimization software often includes supplier management tools that help businesses evaluate supplier performance, track delivery times, manage pricing, and monitor quality. These features enable businesses to build stronger relationships with suppliers, ensure timely deliveries, and negotiate better terms.

5. Warehouse and Order Management

Optimizing warehouse operations is another key aspect of supply chain management. Inventory and supply chain software often includes features for managing warehouses, such as location tracking, pick-and-pack processes, and stock movements. This functionality helps improve the efficiency of warehouse operations, ensuring that products are stored properly and orders are fulfilled quickly.

6. Transportation and Logistics Management

Transportation is a critical part of supply chain optimization, and the software often includes logistics tools that help businesses track shipments, choose the most cost-effective shipping routes, and optimize delivery times. Some solutions integrate with carriers and logistics providers to manage transportation costs, track deliveries, and ensure timely arrivals.

7. End-to-End Visibility and Reporting

End-to-end visibility refers to having a complete overview of the entire supply chain, from procurement to delivery. Inventory and supply chain optimization software often comes with reporting tools that provide insights into key performance indicators (KPIs), such as inventory turnover rates, lead times, order accuracy, and transportation costs. These reports help businesses monitor the efficiency of their supply chain and make data-driven decisions.

8. Data Integration and APIs

For seamless operation, supply chain software needs to integrate with various other business systems, such as Enterprise Resource Planning (ERP), Customer Relationship Management (CRM), and accounting software. Many inventory and supply chain solutions come with APIs that allow for easy integration with existing platforms, ensuring smooth data flow across all systems.

9. Inventory Allocation and Distribution

An effective inventory allocation system helps businesses decide where to allocate inventory across multiple locations or warehouses. By analyzing demand patterns, sales forecasts, and other factors, the software can recommend the best distribution strategy, ensuring products are available where they’re most likely to be needed.

Benefits of Inventory and Supply Chain Optimization Software

1. Improved Efficiency

By automating processes such as inventory tracking, demand forecasting, and order fulfillment, businesses can significantly improve operational efficiency. Tasks that would typically require manual effort are streamlined, allowing businesses to focus on strategic growth rather than day-to-day management.

2. Cost Reduction

Inventory and supply chain optimization software can help reduce operational costs by minimizing stockouts and overstocking, improving warehouse efficiency, and optimizing transportation. Additionally, automation helps reduce the need for manual labor and the associated costs.

3. Enhanced Decision-Making

With access to real-time data, reports, and forecasts, businesses can make better-informed decisions about inventory levels, procurement, and logistics. Data-driven decision-making ensures that resources are used efficiently, minimizing waste and maximizing profitability.

4. Better Customer Service

Optimized supply chains lead to more accurate and timely order fulfillment, which enhances customer satisfaction. By ensuring that products are available when customers need them and deliveries are made on time, businesses can build a reputation for reliability and improve customer retention.

5. Greater Flexibility

Inventory and supply chain optimization software provides businesses with the ability to quickly adjust to changes in demand, supply disruptions, or shifting market conditions. With real-time data and advanced forecasting capabilities, businesses can respond quickly to challenges and maintain control over their operations.

6. Scalability

As businesses grow, so does the complexity of their supply chains. A robust inventory and supply chain optimization solution can scale with the business, allowing it to manage more suppliers, warehouses, and locations without losing efficiency. This scalability ensures that businesses can maintain smooth operations as they expand.

Key Challenges Solved by Inventory and Supply Chain Optimization Software

1. Stockouts and Overstocking

With accurate demand forecasting, real-time inventory tracking, and automated replenishment, businesses can avoid both stockouts and overstocking. The software helps maintain optimal inventory levels, ensuring products are available when needed without tying up excess capital in unsold inventory.

2. Supply Chain Disruptions

The software enables businesses to track and manage suppliers more effectively, ensuring timely deliveries and improving relationships with vendors. In the event of disruptions, businesses can quickly reallocate inventory or adjust supply chain strategies to minimize the impact.

3. Inefficient Warehousing

Inventory and supply chain optimization tools help improve warehouse management, streamlining processes like receiving, picking, packing, and shipping. These improvements lead to faster order fulfillment and better space utilization, which reduces operational costs.

4. Shipping Delays and High Costs

By optimizing transportation routes, reducing lead times, and managing logistics costs, businesses can reduce shipping delays and cut transportation expenses. The software can also help select the most cost-effective shipping providers and routes based on real-time data.

Top Inventory and Supply Chain Optimization Software

1. SAP Integrated Business Planning (IBP)

SAP IBP is an advanced supply chain management solution that helps businesses optimize inventory, demand planning, and logistics. It offers real-time data analysis, integrated forecasting, and collaboration tools, allowing businesses to streamline their supply chain operations.

2. Oracle SCM Cloud

Oracle’s Supply Chain Management Cloud provides end-to-end visibility into inventory, procurement, and logistics. It includes tools for demand forecasting, order management, and supplier collaboration, helping businesses optimize every aspect of their supply chain.

3. Blue Yonder (formerly JDA)

Blue Yonder offers AI-driven supply chain solutions that help businesses optimize inventory management, demand forecasting, and warehouse operations. With advanced analytics, it helps improve efficiency and reduce costs across the supply chain.

4. Kinaxis RapidResponse

Kinaxis RapidResponse is a cloud-based supply chain management platform that offers real-time inventory tracking, demand forecasting, and planning capabilities. It enables businesses to manage their supply chain more efficiently by providing end-to-end visibility and insights.

5. Fishbowl Inventory

Fishbowl offers a comprehensive inventory management solution with supply chain optimization tools, including automated replenishment, demand forecasting, and real-time tracking. It integrates with popular platforms like QuickBooks and Xero, providing businesses with powerful inventory control.

Conclusion

Inventory and supply chain optimization software is crucial for businesses looking to enhance operational efficiency, reduce costs, and improve customer service. By integrating key features like real-time tracking, demand forecasting, automated replenishment, and logistics management, these solutions help businesses streamline every aspect of their supply chain. With the right software, businesses can respond quickly to changes, optimize inventory levels, and ensure timely delivery to customers—resulting in better profitability and long-term growth.

4o mini